Raw wafer

| Wafer type | Description |

| Test wafer (8"/12") | covering the technology node of 0.3um, 0.2um, 0.16um, 0.09um, 0.06um, 0.037um and 0.026um |

| Dummy wafer (8"/12") | Dummy wafer from world top wafer suppliers |

| SIC Substrate (6"/8") | Ultra P, P, D grade |

| SIC Epi/Device wafer (6") | 6" N/N+As (notch 100) EPI and Device wafer |

| GaN wafer (6"/8") | Different substrate for GaN Epi and Device wafers |

Spare parts and Comsumble material_ in Assembly process

Key parts

Item

| Description | Photos |

| Caplliary | From world top suppliers including SPT, Micro-Swiss and GAISER Both standard and BTNK type are provided to cover different design and application |

|

| Rubber tip | Excellent resistance to abrasion, not easy to back sticky, no Stains, no crumbs and no mark Stable ESD resistance Heat resistance: 150℃, 350℃ Minmum tip size 0.07mm, vacuum hold size 0.1mm Different shape by applicatons. |  |

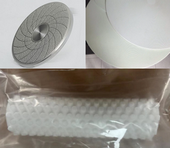

| Grinding Wheel | Possible to grind wafer up to 17um thickness Excellent die strength, roughness and edge performance. Outstanding grinding ability for TSV and Nomral compound wafer Wide application as Disco wheel replacement |  |

| Saw blade | Wide blade witdh range to cover different application Minimized chipping performance Improve productivity by high feed speed better capability on Anti-Ni-corroision, slant cut |  |

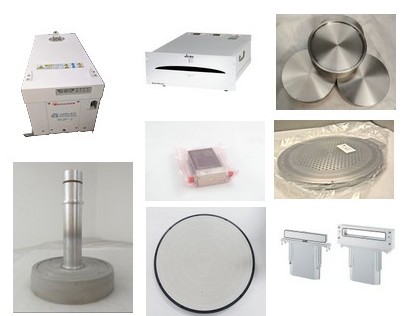

Disco Parts

| Spinner table, chuck table, Bellow, Flange, BBD /NCS AMP sensor , UV Lamp, CCD camera, flow meter etc |  |

Auxillary system | Taping/De-taping system, Wafer expander, Wafer Mounter, UV irradiation system, CO2 bubbler, Diama flow dispenser. |  |

| Jig/Tape | Metal Cassette, Anti-ESD Cassette, Ring, Grinding and cutting tape |  |

Spare parts and Comsumble material_ in Foundry process

--Chiller and Heat Exchanger applied in Dry Etching, Thin film, IMP. Key parameters listed as bellow

| Item | Chiller | Heat Exchanger |

| Temperature range | -20℃-90℃ | -70℃-250℃ |

Control Accuracy

| ± 0.01℃~±0.1℃

| ± 0.01℃~±0.1℃

|

| Power | 3KW~10KW | 200W~200KW |

--Local scrubber for Gas disposition generated in Etching, Thin film and IMP process

--PVD Target, Vacumm Pump, RF Generator, Gate Valver, Showerhead, E-Chuck, Heater, MFC etc. applied in semiconductor equipment suppliers like AMAT/Lam/TEL

--CMP Total solutions

| Item | Description | Photos |

| Slurry | Copper slurry, Barrier Slurry, Dielectric slurry, Tungsten

slurry. Applied in Tier one Foundry already |  |

Post CMP

clean | Effective removal of particle and residues after W,Al,Cu,SiN

polishing.

Remove by-products on Pads, extenstion of pad lifetime

and surface defect reduction on polised wafer. |

Slurry

Central

Supply | Professional Slurry Supply system |

|

| Parts | Pad, Conditioner, Brush |

|

Process Tools

| Application | Function | Description |

| Foundry | CVD/PVD/CMP/Furnace/Etch/WET Etch, Scrubber Clean | 6"/8"/12" Refurbished process tools |

| Foundry | CD-SEM, Thickness measurement, Profile Measurement | Offer Both new and Refurbished metrology tools |

| Assembly | Wafer Saw | 6"/8"/12" both new and refurbished tools Basic Function wiht multiple piece cutting, Auto focus, Pattern recognition, Alignment. Optional Functions include NCS, Kerf check, Blade breakage detection,working piece recognition. |

| Lab | Failure analysis and Reliability | Nano probing, FIB, SEM, OM THS, TC, HAST standard chamber and test kits. Customized thermo stressing application system |